Looking to master MIG welding? This comprehensive guide will cover everything from selecting the right machine to setting it up and mastering effective welding techniques. Whether you’re a novice or experienced welder, you’ll learn essential tips and methods to excel in MIG welding machine welding.

Key Takeaways

- MIG welding, known for its user-friendliness, is ideal for various materials including aluminum, steel, and stainless steel, suitable for both professionals and beginners.

- Proper setup, adjustment of machine settings, and strict safety precautions are crucial for achieving optimal performance and ensuring safe operation during MIG welding.

- Regular maintenance, including cleaning, troubleshooting common issues, and timely replacement of consumables, is essential for the durability and performance of MIG welding machines.

Understanding MIG Welding Machines

MIG welding, or Metal Inert Gas welding, is a popular welding process known for its versatility and ease of use. It involves feeding a continuous solid wire electrode through a welding gun, creating a weld puddle that joins metal pieces together. This method is particularly effective for MIG welding sheet metal, including aluminum, steel, and stainless steel. One of the key advantages of MIG welding is its user-friendliness, making it accessible even for less skilled welders to achieve quality welds. MIG welding is technically a form of Gas Metal Arc Welding (GMAW).

A thorough understanding of the components and working mechanisms of a MIG welding machine is key to achieving optimal results. We’ll look at the essential parts, their functions, and how to select the right machine for your specific needs.

Components of a MIG Welding Machine

A MIG welding machine comprises several key components that work together to ensure a successful welding process. The power source, which can be either a transformer or an inverter, generates the necessary electrical current. The wire feeder, consisting of a motor and a drive roller, controls the speed at which the welding wire is fed.

For mild steel, a common shielding gas is a 75% argon / 25% CO₂ blend. For aluminum, pure argon is typically used as the shielding gas to protect the weld pool from contamination and enhance weld quality.

How MIG Welding Machines Work

MIG welding machines operate by:

- Feeding a continuous solid wire electrode into the weld puddle to join metal pieces.

- Using a machine-fed method to ensure a consistent supply of the wire electrode, which is melted to create the weld.

- Employing shielding gas to protect the weld pool from atmospheric contamination, resulting in a clean and strong weld.

Selecting the Right MIG Welding Machine

Choosing the right MIG welding machine involves considering several factors, such as:

- The thickness of the material being welded to ensure suitable penetration and strength.

- MIG welding can be used for sheet metal as thin as 26 gauge(≈ 0,45 mm), though proper settings and technique are essential to avoid burn-through.

- The type of metal, with mild steel being an example of suitable material.

Additionally, the specific application for the welding task and your budget are important considerations when selecting a MIG welding machine.

Setting Up Your MIG Welding Machine

Properly setting up your MIG welding machine is the first step to achieving optimal performance. Correct assembly and connection to a power source are crucial starting points.

We’ll guide you through machine preparation, adjusting settings, and necessary safety precautions.

Preparing the Machine

Before starting:

- Ensure the machine is correctly assembled and connected to a suitable power source.

- Choose the appropriate wire type for the metal being welded.

- Load the spool correctly to prevent tangles and ensure smooth feeding.

Regular cleaning of the MIG gun liner is essential for smooth filler wire feeding and reducing issues.

Adjusting Settings

Adjusting settings such as voltage and wire feed speed is critical for achieving the desired weld bead. Voltage adjustments determine the height and width of the bead, while wire feed speed affects penetration and weld quality.

Typical gas flow is around 10–15 CFH(4,7–7,1 l/min), but this may vary depending on material, joint type, and shielding gas.

Safety Precautions

Safety is paramount in MIG welding. Always wear appropriate protective gear, including gloves, a welding helmet, and fire-resistant clothing. Proper ventilation is necessary to avoid inhaling harmful fumes.

Additionally, be cautious when handling the shielding gas, especially carbon dioxide, to prevent accidents.

Techniques for Effective MIG Welding

Mastering effective MIG welding techniques is key to achieving strong and clean welds. These techniques include:

- Proper posture

- Holding the welding gun correctly

- Advanced methods like tack welding

- Skip welding

These techniques will enhance your welding skills and outcomes.

Here are the specifics of these techniques.

Proper Welding Technique

Holding the welding gun with both hands offers better stability and control. Applying anti-spatter spray on consumables can reduce cleaning time and improve efficiency with a welding torch.

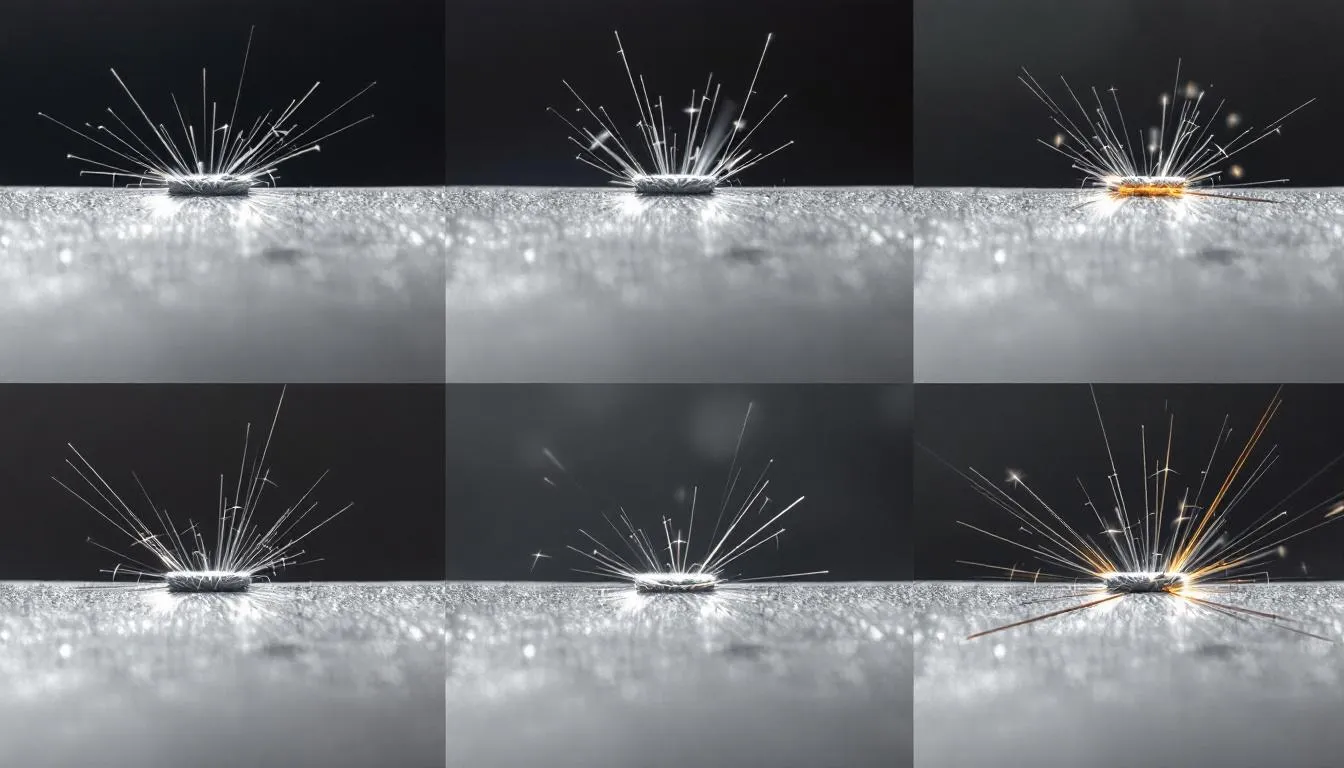

These practices help maintain a consistent flow of molten metal, minimize spatter, and offer better control over the weld pool.

Tack Welding

Tack welding temporarily holds metal pieces in position before final welding. Key points to consider:

- Often, leaving a small gap (about 1 mm) between thin pieces can help ensure full penetration.

- Use a tack weld timer for consistency.

- This technique is particularly useful for thin metals, as it helps prevent distortion.

Skip Welding

Skip welding creates intermittent welds to reduce heat input and avoid distortion in thin materials. It’s ideal for welding sheet metal, minimizing the risk of overheating and ensuring a clean, precise weld.

Common Issues and Solutions in MIG Welding

MIG welding can present several challenges, including spatter, burn-through, and porosity. Understanding these issues and their solutions is crucial for maintaining weld quality.

We’ll explore how to deal with these common problems effectively.

Dealing with Spatter

High voltage settings can increase spatter. Adjust voltage settings appropriately and maintain a steady hand to minimize spatter.

Anti-spatter spray can also help keep the weld area clean and reduce post-weld cleanup time.

Preventing Burn-Through

Preventing burn-through in thin materials requires careful control of excessive heat, heat input, and material thickness. Lowering voltage and wire speed, and using smaller wire diameters can help with thinner materials and thin sheets, resulting in less heat.

Using backing bars to dissipate heat and maintaining a fast travel speed can also reduce the risk of burn-through due to the heat generated.

Fixing Porosity

Porosity, caused by trapped gas, weakens the weld. Ensure surfaces are clean, use the correct shielding gas mix, and maintain adequate gas coverage.

Advanced MIG Welding Techniques

Advanced MIG welding techniques can significantly enhance your welding skills and outcomes. Techniques like pulsed MIG welding and spray transfer method offer improved control and weld quality.

Here are the details of these advanced methods.

Pulsed MIG Welding

Pulsed MIG welding is beneficial for thin materials, offering improved heat control and reducing burn-through risk. It minimizes spatter and allows precise adjustments to the weld pool size for higher quality welds.

Spray Transfer Method

The spray transfer method is effective for thick materials, providing deep penetration and high deposition rates. It produces smooth, high-quality welds with minimal spatter, ideal for challenging tasks.

Using Flux-Cored Wires

Flux-cored wires are well-suited for outdoor welding because they are less affected by wind. They also provide good penetration on thicker materials, making them useful for heavy-duty applications.

Maintaining Your MIG Welding Machine

Regular maintenance of your MIG welding machine is crucial for ensuring its longevity and optimal performance. Covering the machine when not in use protects it from dust and debris.

We’ll discuss routine maintenance tasks, troubleshooting common issues, and replacing consumables.

Routine Maintenance Tasks

Always close the shielding gas cylinder valve after use to prevent leaks and reduce gas waste.

Troubleshooting Common Issues

Wire feeding issues often stem from a dirty or damaged liner in the MIG gun. Regular inspection and cleaning can prevent overheating and ensure smooth operation.

Checking gas hoses and connections for leaks is crucial for maintaining welding quality.

Replacing Consumables

Replacing worn-out consumables is vital for optimal performance. These consumables include:

- Nozzles

- Contact tips

- Gas diffusers

- Liners

- Power pins

The choice of nozzle material, whether brass or copper, affects performance and spatter resistance.

Proper installation of MIG gun liners and using the correct gas diffuser are crucial for preventing weld defects and improving efficiency.

Applications of MIG Welding

MIG welding is widely utilized across various industries due to its efficiency and adaptability. Its ease of use and cost-effectiveness compared to other welding methods, such as TIG welding, make it a preferred choice for many professionals and DIY enthusiasts alike. Additionally, understanding TIG welding processes can enhance a welder’s skill set, especially when considering both MIG and TIG techniques.

Here are the diverse applications of MIG welding.

Automotive Industry

MIG welding is essential in the automotive sector for both MIG production and repair. It’s extensively used for joining body panels and structural components, ensuring strong, reliable MIG welds.

The technique’s ability to efficiently spot weld thin metals and aluminum makes it ideal for automotive applications, where precision and durability are essential. Additionally, working with thin sheet metal improves the overall quality of the welds.

Construction and Fabrication

In construction, MIG welding is favored for creating robust connections in large metal structures and frames. Its precision in handling sheet metal fabrication and welding thin materials ensures the integrity and strength of projects.

This welding method is also highly effective for fabricating stainless steel and carbon steel components, making it a versatile tool in the construction and fabrication sectors, including applications that utilize stick welding, stitch weld, and the arc welding process.

Home Projects and DIY

MIG welding is popular among DIY enthusiasts for its user-friendly approach, enabling custom metal projects and repairs at home. Whether building furniture, repairing fixtures, or crafting unique metalwork, MIG welding offers the flexibility and ease needed for various home projects.

Summary

Mastering MIG welding opens a world of possibilities, from professional applications in the automotive and construction industries to DIY projects at home. By understanding the components and workings of MIG welding machines, setting them up correctly, and employing effective welding techniques, you can achieve strong, clean, and reliable welds. Regular maintenance and troubleshooting ensure your equipment remains in top condition, while advanced techniques like pulsed MIG welding and the spray transfer method offer enhanced control and quality. Dive into the world of MIG welding with confidence and creativity, knowing you’re equipped with the knowledge and skills for success.

Frequently Asked Questions

What is the main advantage of MIG welding over other welding methods?

The main advantage of MIG welding is its ease of use, allowing less skilled welders to produce quality welds, while also being versatile and cost-effective compared to methods like TIG welding.

How do I prevent spatter when using a MIG welder?

To effectively prevent spatter when MIG welding, maintain appropriate voltage settings, use a steady hand, and consider applying anti-spatter spray. These measures will help achieve cleaner welds.

What should I consider when choosing a MIG welding machine?

When choosing a MIG welding machine, prioritize the thickness of the materials you’ll be working with, your specific welding applications, and your budget. These factors will ensure you select a suitable and effective machine for your needs.

How can I prevent burn-through when welding thin metals?

To prevent burn-through, reduce the voltage and wire feed speed, utilize a smaller wire diameter, use backing bars to dissipate heat, and maintain a fast travel speed. These adjustments will help you achieve cleaner welds without damaging the base material.

What are the benefits of using flux-cored wires in MIG welding?

Using flux-cored wires in MIG welding offers excellent resistance to wind and environmental conditions, making them ideal for outdoor use. Additionally, they are highly effective for welding thicker materials, which is beneficial for heavy-duty applications.