Key Takeaways

-

Mechatronics integrates mechanical, electrical, and computer systems to create intelligent automation across manufacturing, automotive, and healthcare.

-

Robotics develops autonomous machines capable of decision-making using AI, machine learning, and advanced sensors.

-

Both fields offer strong career prospects. According to the U.S. Bureau of Labor Statistics, mechatronics technologists earn a median salary of $75,710 annually, while robotics engineers often earn even more.

-

The global robotics market is projected to grow at 29.4% annually through 2032 (Market Research Future), while mechatronics continues expanding in Industry 4.0.

-

Success in either field requires interdisciplinary knowledge of engineering, programming, control systems, and emerging technologies such as IoT and AI.

What Are Mechatronics and Robotics?

Mechatronics and robotics are closely linked disciplines that drive modern automation. Together, they are reshaping industries from automotive and healthcare to aerospace and consumer electronics.

-

Mechatronics combines mechanical engineering, electronics, and computer science to design intelligent systems. The term was coined in the 1980s by Ko Kikuchi. Mechatronics systems integrate sensors, actuators, and embedded software to optimize performance.

-

Robotics builds on these principles but focuses on autonomous machines that can perceive their environment, process information, and act with minimal human input. From the first industrial robots in the 1950s to today’s AI-driven systems, robotics has advanced toward self-learning and adaptive behavior.

These technologies enhance productivity, reduce human error, and support advanced solutions — from cruise control in cars to robot-assisted surgery.

Understanding Mechatronics Engineering

Mechatronics engineering unites mechanical, electronic, and computer systems into intelligent solutions. It emphasizes system integration: ensuring all components work seamlessly.

Examples include:

-

Anti-lock braking systems (ABS)

-

Autofocus in cameras

-

CNC machines in advanced manufacturing

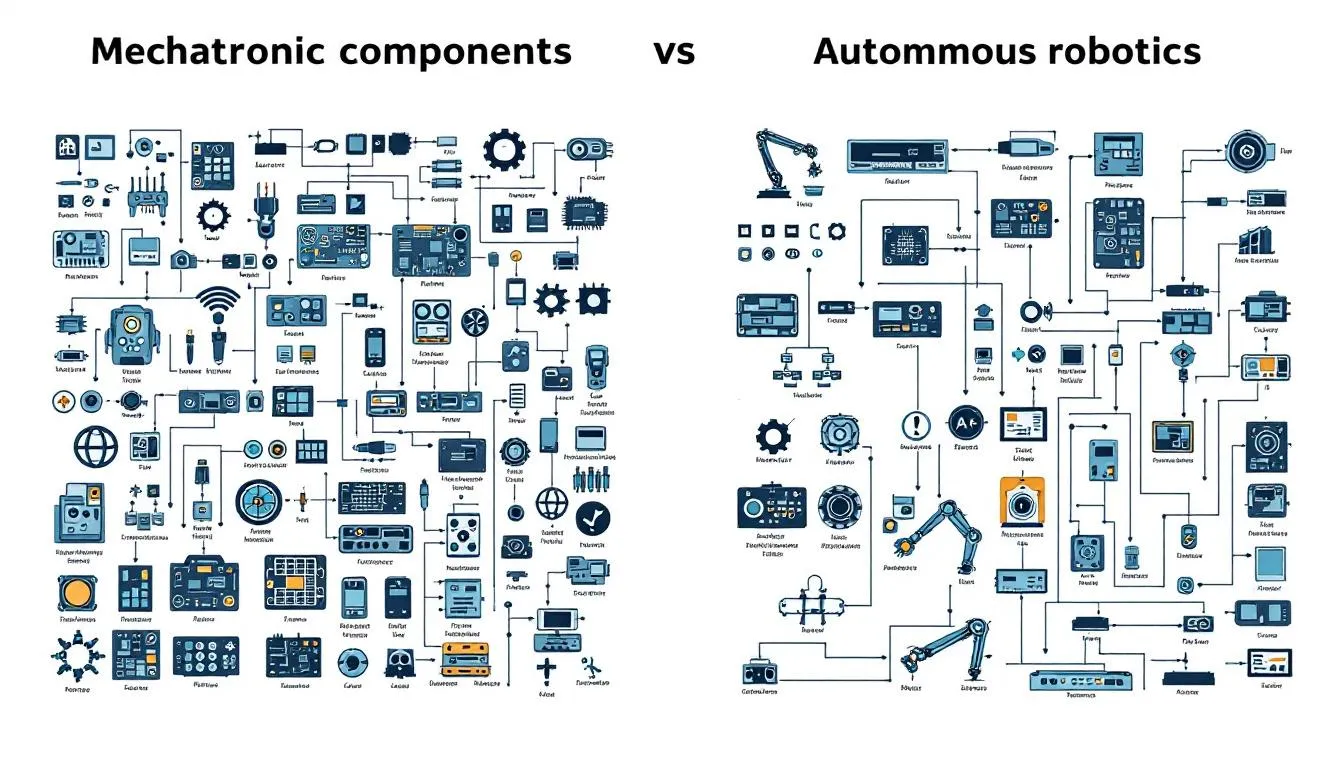

Core Components of Mechatronic Systems

-

Mechanical Systems – actuators, gears, sensors, and motion control provide the physical foundation.

-

Electronic Systems – microcontrollers, power management, and communication interfaces enable smart operation.

-

Control Systems – feedback loops, PID controllers, and adaptive algorithms maintain stability and efficiency.

-

Software Integration – embedded software, real-time OS, and tools like MATLAB or Simulink connect all parts.

Mechatronics Applications

-

Automotive: transmission control, engine management, autonomous driving components.

-

Manufacturing: automated assembly lines, precision machining, and quality control.

-

Healthcare: diagnostic devices, robotic surgery, medical imaging.

-

Aerospace: avionics, navigation, and flight control systems.

Understanding Robotics Technology

Robotics emphasizes autonomous machines with AI and machine learning. Robots can sense, decide, and act — often in unpredictable environments.

Key focus areas:

-

Human-robot collaboration (cobots)

-

AI-driven adaptive behavior

-

Autonomous vehicles, drones, and service robots

Core Technologies in Robotics

-

Artificial Intelligence – machine learning, neural networks, computer vision

-

Mechanical Design – arms, locomotion, end-effectors

-

Sensor Technologies – LiDAR, cameras, force sensors, proximity detectors

-

Control Systems – real-time processing, path planning, obstacle avoidance

Robotics Applications

-

Industrial Robotics: welding, material handling, inspection

-

Service Robotics: cleaning, delivery, customer service, personal assistance

-

Medical Robotics: surgical systems, rehabilitation devices

-

Exploration Robotics: Mars rovers, underwater vehicles, disaster response

Mechatronics vs Robotics: Key Differences

-

Scope: Mechatronics focuses on system integration; robotics narrows in on autonomy.

-

Technical Approach: Mechatronics emphasizes optimization; robotics emphasizes AI and adaptive behavior.

-

Applications: Mechatronics dominates in manufacturing, automotive, consumer products. Robotics thrives in autonomy-driven tasks like drones, cobots, and exploration.

Career Opportunities

Both fields offer strong prospects:

-

Mechatronics Careers: automation engineer, manufacturing engineer, control systems designer.

-

Robotics Careers: robotics engineer, AI specialist, autonomous systems developer.

Job outlook:

-

Mechatronics: steady 4% growth (2016–2026, BLS).

-

Robotics: projected 29.4% annual growth through 2032 (MRFR).

Education and Skills

-

Fundamentals: mechanical, electrical, and computer science basics

-

Programming: Python, C++, MATLAB; ROS for robotics

-

Tools: CAD, simulation platforms, embedded systems

-

Soft Skills: problem-solving, teamwork, project management

Pathways:

-

Bachelor’s or Master’s degrees in mechatronics, robotics, or related fields

-

Certifications for specialization

-

Internships and lab experience for hands-on learning

Future Trends and Innovations

-

AI Integration: adaptive control, predictive maintenance

-

IoT Connectivity: smart factories, real-time data optimization

-

Sustainable Technologies: energy efficiency, green materials

-

Industry 4.0: cyber-physical systems and digital manufacturing

Emerging tech:

-

Collaborative robots (cobots)

-

Digital twins

-

Edge computing

-

Advanced materials and smart sensors

Frequently Asked Questions

What’s the main difference between mechatronics and robotics?

Mechatronics optimizes and integrates systems; robotics focuses on autonomy and AI-driven behavior.

Do I need a specific degree?

Not always. Mechanical, electrical, or computer science degrees with specialization are common pathways.

Which field has better growth?

Robotics shows faster growth (29.4% annually), while mechatronics offers steady demand in established industries.

Can I switch between fields?

Yes. Both share foundations, making transitions common.

Which programming languages are most important?

Python and C++ are essential. MATLAB is widely used in mechatronics; ROS is important for robotics.