Key Takeaways

-

Custom power supplies are engineered to meet specific voltage, current, environmental, and form-factor requirements that off-the-shelf units often cannot cover.

- A robust design flow covers topology selection, component sizing, thermal design, PCB layout, and safety/EMC compliance (e.g., IEC/UL 62368-1, IEC 60601-1 for medical, CISPR 32/35 for EMC).

- Modern switching topologies (e.g., LLC resonant, synchronous rectification, GaN/SiC) can typically achieve ~90–95% peak efficiency in optimized designs.

- Validation includes load/line regulation, ripple, transient response, thermal, reliability, and EMC testing.

- Cost optimization balances performance, compliance, manufacturability, and lifecycle/obsolescence planning.

Why Custom Power Supplies?

Modern systems—from renewable energy and telecom to medical devices and battery energy storage—often require non-standard voltages, isolation, reliability levels, or mechanical envelopes. Custom design aligns the power stage to the real load profile, integration needs (e.g., BMS, PLC, CAN/PMBus), and the regulatory landscape.

What “Custom” Actually Means

Custom power supply engineering spans:

-

Electrical: topology choice, magnetics, semiconductors (Si, GaN, SiC), control algorithms.

-

Mechanical/Thermal: form factor, cooling strategy, heatsinks, airflow, vibration constraints.

-

Safety & EMC: insulation system, creepage/clearance, protective earth, emissions/immunity.

-

System Integration: interfaces (I²C/PMBus/CAN/Ethernet), telemetry, and energy management.

Core Subsystems

-

Input stage: inrush limiting, surge protection, filtering, and (if required) PFC.

-

Power stage/topology (the “heart”): determines efficiency, power density, and EMI behavior.

-

Control: analog PWM (e.g., current-mode) or digital (adaptive loops, telemetry, PFC).

-

Output stage: rectification, synchronous stages, LC filtering, sense/feedback networks.

Common Topologies (when to use what)

-

Flyback (to ~150 W): simple, isolated, multi-output capable. Great for chargers/aux rails.

-

Forward/Two-transistor forward (~100–500 W): higher efficiency and lower ripple than flyback.

-

LLC resonant (wide power range): very high efficiency with soft switching and low EMI—popular for high density and battery-related applications.

-

Half-/Full-Bridge (≥1 kW): robust at higher power; good regulation with appropriate control and magnetics.

Control, Protection & Feedback

-

Controllers: PWM (e.g., current-mode UCx family) or digital controllers for PFC, telemetry, adaptive dead-time, and multi-phase coordination.

-

Protection: Overvoltage (OVP), Overcurrent/Overload (OCP/OLP), Short-circuit (SCP), Overtemperature (OTP), input UVLO/OVLO; with coordinated fault responses.

-

Feedback stability: ensure adequate gain/phase margin and fast transient response (especially for dynamic loads/BMS).

Requirements & Specifications (get these right first)

-

Inputs: voltage windows, frequency, hold-up time, PFC requirements, surge/ESD.

-

Outputs: voltages, current ranges, ripple/noise targets, regulation, sequencing, dynamic load steps.

-

Environment: temp (often −40…+85 °C industrial), altitude, humidity, vibration/shock.

-

Safety: insulation classes, creepage/clearance, PE bonding, fault conditions.

-

Power quality & EMC: harmonics, PF, CISPR 32/35 targets, grid codes if applicable (for inverters/ESS).

-

Battery specifics (if relevant): CC/CV profiles, cell chemistry, balancing, BMS comms.

Design Process (end-to-end)

-

Requirements & risk analysis (including future variants and lifecycle).

-

Topology trade-off (efficiency, density, isolation, cost, compliance).

-

Component selection: magnetics, capacitors (lifetime/ESR), semis (GaN/SiC), connectors/fuse/NTC/TVS.

-

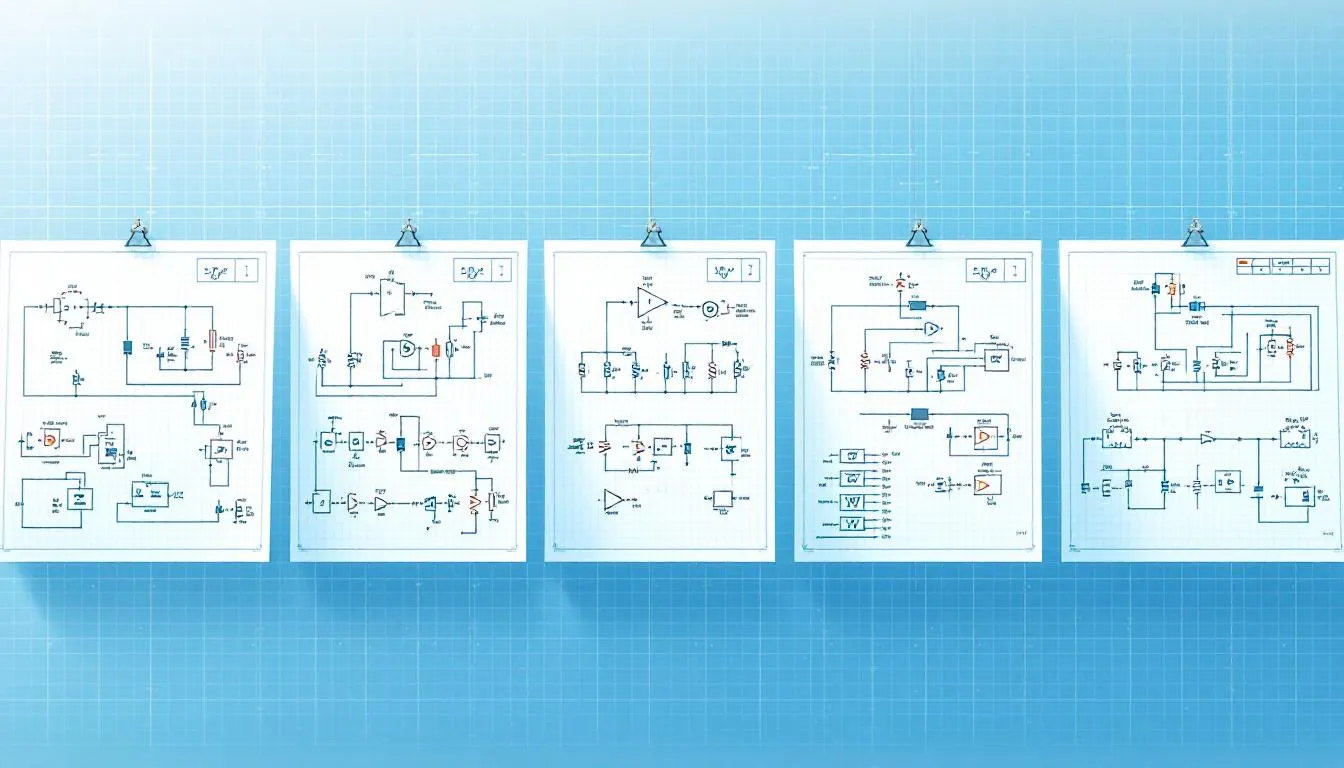

Simulation:

-

SPICE/LTspice/PSIM for steady-state and transient behavior.

-

Thermal (e.g., FloTHERM/ICEpak) for junction and system temps.

-

EMC pre-analysis for layout/filter strategies.

-

-

Prototyping: EVB/breadboard → first-article PCB.

-

Layout optimization: loop areas, switch nodes, return paths, thermal vias/copper pours, creepage/clearance, current density.

-

Testing & iteration: tune loops, refine thermals and EMI filters.

-

Pre-compliance: safety, CISPR 32 (emissions), CISPR 35 (immunity), sector-specific add-ons.

-

Design freeze → DFM/DFT → pilot build → certification → ramp.

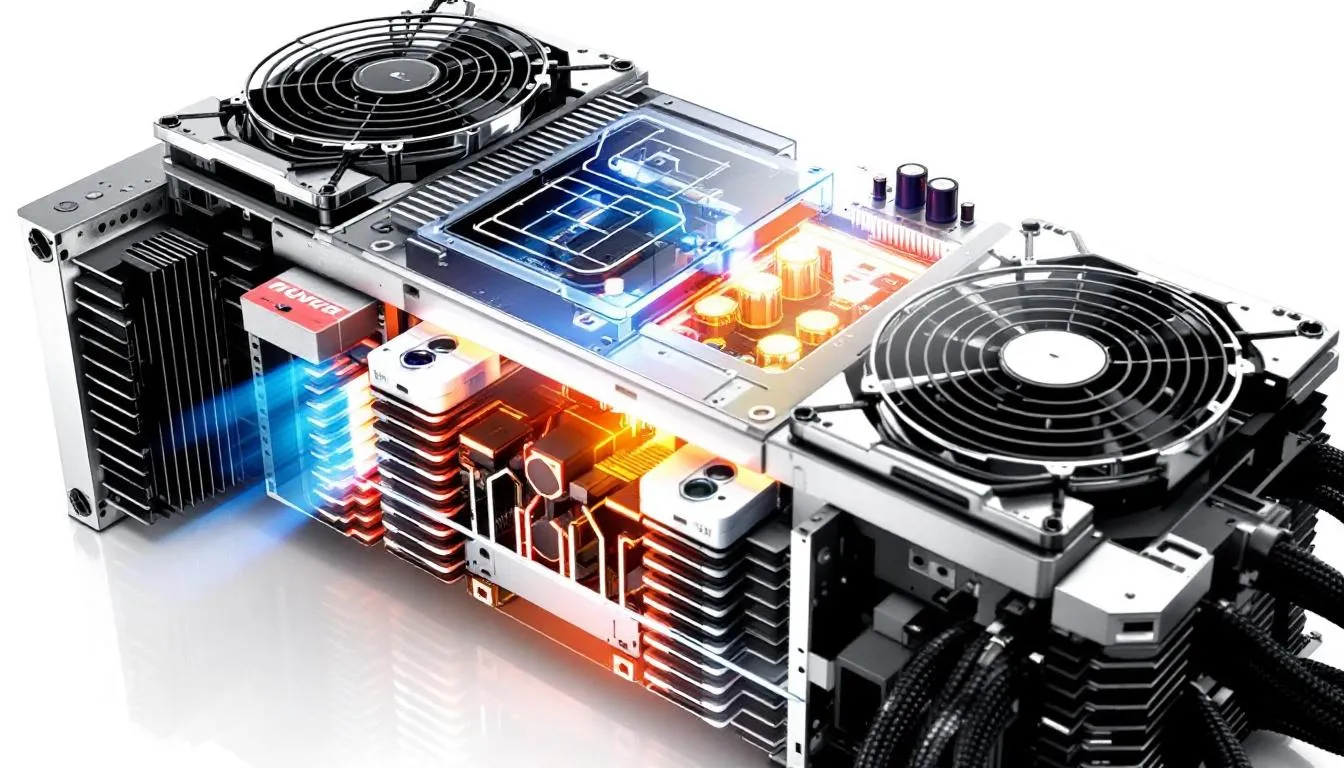

Thermal Management in Custom Power Supply Design

- Loss accounting: conduction, switching, core/copper, gate-drive, auxiliary rails.

- Cooling choices: natural convection, forced air, heat pipes, cold plates/liquid (for high density).

- Layout for thermals: hot-spot spacing, keep-out zones around temp-sensitive parts, airflow paths.

- Validation: worst-case ambient, altitude derating, temp cycling, capacitor hotspot checks.

Safety & EMC

-

IT/AV & industrial: IEC/UL 62368-1 (replacing 60950-1/60065).

-

Medical: IEC 60601-1 (safety) and IEC 60601-1-2 (EMC).

-

EMC (general): CISPR 32 (emissions) + CISPR 35 (immunity) or regional equivalents (e.g., FCC Part 15).

-

Efficiency/ErP: EU Ecodesign (e.g., EU 2019/1782 for external PSUs); 80 PLUS is a voluntary label frequently used in IT/server contexts.

-

Testing: hi-pot, PE/ground bond, leakage current, surge/ESD/EFT, conducted/radiated emissions, conducted/radiated immunity.

Verification & Validation

-

Electrical: load/line regulation, ripple/noise, efficiency maps (across load/temp), hold-up time.

-

Dynamics: step-load transient, startup/shutdown sequencing, hiccup/latched faults.

-

Reliability: burn-in, HALT/HASS, MTBF prediction, component derating review.

-

Environmental: thermal chambers, humidity, vibration/shock to target profiles.

-

EMC: iterative filter/layout tuning before formal labs.

Applications & Notes

-

Medical: low leakage, isolation, multiple isolated rails; stringent EMC.

-

Battery Energy Storage (BESS): bidirectional stages, high efficiency over CC→CV, tight comms with BMS/EMS.

-

Aerospace/Defense: harsh environment, MIL-STD-461/810 if applicable.

-

Industrial automation: noise immunity, fieldbus/PLC integration, wide temp, redundancy options.

-

Telecom: hot-swap, ORing/redundancy, PMBus telemetry, thermal at altitude.

-

Renewables/grid: grid codes (for inverters), anti-islanding, harmonic limits; hybrid with storage.

Cost Optimization

-

Value engineering: right-sizing specs, alternate parts with equivalent reliability.

-

DFM/DFT: panelization, test points, ICT/functional test time reduction.

-

Sourcing & lifecycle: second-source strategy, obsolescence watch, NPI ramp plans.

-

Volumes: MOQ/tooling versus part customization (especially magnetics).

Emerging Trends

- GaN/SiC: higher frequency, lower loss → smaller magnetics and higher density.

- Digital power: adaptive loops, telemetry, predictive maintenance, PMBus/CAN/Ethernet.

- Modularity: reusable power stages/control bricks to speed variants.

- IoT/Cloud: remote monitoring, field updates, fleet-level analytics.

- Miniaturization: advanced packaging, better thermal interfaces, EMI-friendly layouts

Conclusion

Custom power supply design is more than just selecting components—it is a multidisciplinary engineering process that balances efficiency, safety, compliance, cost, and long-term reliability. As electronic systems become more demanding, off-the-shelf solutions increasingly fall short.

By following a structured design process—from requirements analysis and topology selection to thermal management, EMC optimization, and rigorous validation—engineers can deliver power supplies that are technically robust and compliant with international standards.

Looking ahead, wide bandgap semiconductors, digital control, modular architectures, and IoT integration will continue to shape the next generation of custom power supplies. Companies that invest in tailored solutions today will gain higher performance, better reliability, and longer lifecycle value in tomorrow’s applications.

FAQs

What’s a typical development timeline?

For a single-output custom PSU, ~12–20 weeks is common (spec & design 3–4, prototype 6–8, refinement & validation 4–8). Complex certification, medical, or ESS integrations can extend this.

When do I need custom vs. off-the-shelf?

Choose custom when you need non-standard outputs, isolation levels, harsh environment ratings, unusual mechanics, specific interfaces/telemetry, or certified compliance the catalog units can’t meet.

What MOQs are typical?

Commonly ~100–1000 units, depending on complexity and whether NRE is amortized. Lower volumes are possible with separate NRE.

How does power density compare?

With GaN/SiC, LLC, and optimized thermal/layout work, custom designs can achieve higher density than general-purpose supplies; values depend on constraints, but 15–25 W/in³ is typical for modern designs.

Which certifications are most common?

-

IEC/UL 62368-1 (IT/AV & industrial)

-

IEC 60601-1/-1-2 (medical)

-

DO-160 (aerospace, if applicable)

-

ISO 26262 (automotive functional safety)

-

EMC typically references CISPR 32/35 or regional equivalents

Note: Requirements depend on the end application and market; always define them during the specification phase.