Electronic Manufacturing Services (EMS) providers help OEMs design, industrialize, build, test, and deliver electronic products. This guide explains EMS scope, benefits, selection criteria, industry use cases, and future trends.

Key Takeaways

-

EMS partners can cover design support, PCB assembly (SMT/THT), testing, system integration (box build), logistics, and after-sales services.

-

Outsourcing to EMS providers can reduce cost and time-to-market while giving access to specialized technology and experienced teams.

-

Typical EMS industries include aerospace & defense, medical, automotive, telecoms, and industrial electronics with high quality requirements.

-

Choosing a provider should consider certifications, industry experience, technical depth, supply-chain strength, and cultural fit.

-

Trends shaping EMS include automation, digitalization (Industry 4.0), sustainability, and emerging applications (IoT, EVs, 5G, edge AI).

What Are Electronic Manufacturing Services (EMS)?

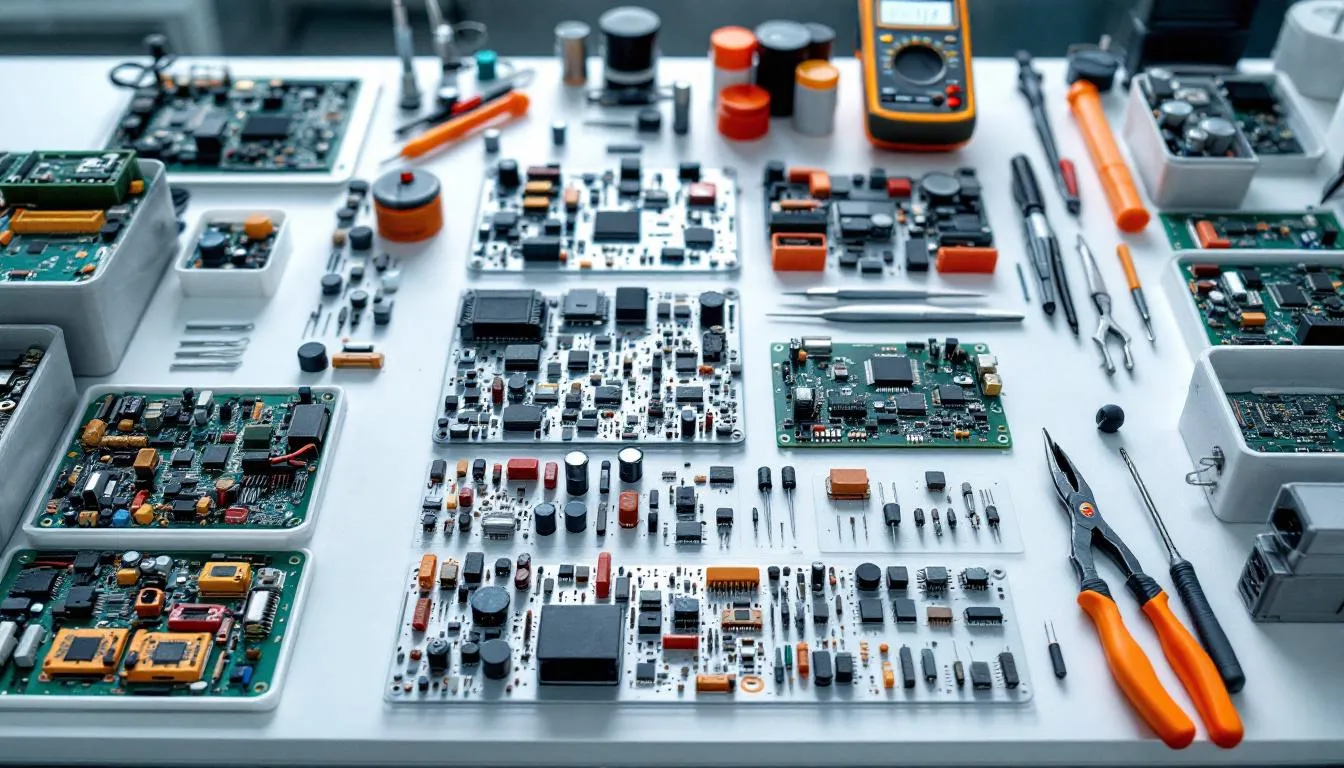

Electronic Manufacturing Services are contract manufacturing and value-added services that EMS companies provide to Original Equipment Manufacturers (OEMs). Unlike narrow build-to-print relationships, modern EMS providers act as strategic partners across the product lifecycle—from design for manufacturability (DfM) and prototyping to series production, testing, compliance, logistics, and service.

This integrated model helps OEMs access specialized processes, skilled personnel, and global supply chains without large in-house investments. Many EMS partners also support component lifecycle/obsolescence management, regulatory compliance, and end-to-end supply-chain planning.

Core EMS Services & Capabilities

PCB Assembly: SMT, THT & Mixed Technology

-

SMT for miniaturized, high-density assemblies; supported by AOI, X-ray, and in-circuit/functional testing.

-

Through-hole (THT) for higher mechanical strength or power handling.

-

Mixed technology assemblies combine SMT and THT to balance performance, reliability, and cost.

System Integration & Box Build

-

Complete electromechanical assembly: enclosures, mechanicals, wire harnesses, cable looms, firmware/software loading, and final test.

-

Project management across mechanical, electrical, and software domains; environmental and regulatory verification where applicable.

Custom Cable Assembly & Interconnects

-

IPC-compliant hand soldering, over-molding for ruggedization, strain relief, and environmental protection.

-

Electrical and mechanical testing (continuity, insulation, pull tests) before shipment.

Design & Engineering Support

-

DfM/DfT reviews to improve yield and reduce cost.

-

Component engineering (selection, alternates, lifecycle and obsolescence planning).

-

Value engineering and cost optimization (process improvements, substitutions where acceptable).

-

Compliance guidance aligned to target markets and industries.

Benefits of Partnering with an EMS Provider

-

Cost efficiency: Shared infrastructure, bulk procurement, and optimized processes can lower total manufacturing cost.

-

Faster time-to-market: Established lines, qualified processes, and experienced teams can accelerate NPI.

-

Access to technology: Advanced equipment and testing capability without major capex.

-

Risk management: Diversified sourcing, structured quality systems, and traceability reduce disruption risk.

-

Focus on core: OEMs can concentrate on product strategy, IP, and customers while outsourcing manufacturing complexity.

How to Select the Right EMS Partner

Technical Capabilities & Quality

-

Certifications: e.g., ISO 9001 (quality management). For regulated sectors consider ISO 13485 (medical) or AS9100 (aerospace).

-

Equipment & processes: modern SMT lines, automated inspection, robust test strategies (ICT, FCT, ESS where relevant).

-

Engineering depth: DfM/DfT support, test development, reliability engineering.

-

Supply chain strength: authorized sourcing, traceability, proactive obsolescence management.

Industry Experience & References

-

Proven work in your vertical (medical, aerospace & defense, automotive, industrial, telecoms).

-

Case studies/references demonstrating similar complexity and compliance requirements.

-

Regulatory know-how for target markets.

Partnership & Cultural Fit

-

Clear communication and project management, transparent KPIs.

-

Flexibility for volume ramps, design changes, and new tech adoption.

-

Continuous improvement mindset and aligned business ethics.

-

Geography/time zone fit for build location and program teams.

EMS Market & Applications

EMS spans thousands of providers worldwide—from global multi-site manufacturers to regional specialists. Asia-Pacific is prominent in high-volume consumer production, while Europe and North America often focus on regulated and high-mix applications. Key sectors include medical, aerospace & defense, automotive, industrial automation, telecommunications, and consumer electronics.

High-Mix, Low-Volume (HMLV) Manufacturing

-

Why it matters: Supports diverse product portfolios and frequent design updates.

-

Benefits: Lower inventories, faster change implementation, niche market responsiveness.

-

What to check: Planning systems, setup optimization, operator skill, and quality consistency across variants.

Current Challenges in Electronics Manufacturing

-

Supply chain volatility & shortages: Requires multi-sourcing and inventory strategies.

-

Component obsolescence: Needs lifecycle tracking and redesign planning.

-

Counterfeit risk: Mitigated by authorized channels, incoming inspection, and traceability.

-

Quality at high density: Demands advanced inspection/testing and process control.

-

Regulatory complexity: Varies by sector/region; requires maintained competence.

-

Talent constraints & upskilling: Ongoing training to sustain capability.

Future Trends Shaping EMS

Automation & Industry 4.0

-

Robotics for placement, handling, and assembly to improve consistency and throughput.

-

Smart factory/IoT data for real-time monitoring, OEE, and predictive maintenance.

-

AI/analytics for defect prediction, yield optimization, and supply planning.

-

Digital twins to simulate processes and de-risk changes.

Sustainability

-

Energy-efficient operations, waste reduction, and sustainable materials.

-

Circularity: design for repair, reuse, and recyclability where feasible.

-

Green supply chains and documented environmental performance.

Emerging Applications

-

IoT/edge devices: connectivity, miniaturization, power efficiency.

-

EV/power electronics: high-reliability, thermal management, EMC.

-

5G/RF: precision assembly and RF testing.

-

Medical innovation: biocompatibility, traceability, regulated QMS.

Frequently Asked Questions

What’s the difference between EMS and ODM?

EMS manufactures to a client’s design and can support industrialization/testing/logistics. ODM also offers full product design that clients may rebrand.

How do EMS providers reduce counterfeit risk?

By sourcing from authorized channels, using traceability and incoming inspections, and applying authentication/testing where appropriate.

Typical lead times from prototype to production?

Highly dependent on complexity, test strategy, and component availability. Simple products can move in weeks; complex, regulated systems may take months. Early EMS engagement often shortens timelines.

How is IP protected?

With NDAs, controlled data access, secure IT systems, restricted areas, and employee confidentiality policies.

Which certifications matter for medical devices?

Commonly ISO 13485. Depending on markets/processes, also ISO 14971 (risk management) and relevant registrations/validations.