A programmable power supply gives you precise control over voltage and current, essential for diverse testing and operational tasks. This article will explain what programmable power supplies are. It will also cover their key advantages and how to select the best one for your needs.

Key Takeaways

- Programmable power supplies offer enhanced flexibility and precision. They do this by allowing adjustable voltage and current settings, which makes them suitable for diverse applications.

- Key features of these power supplies include autoranging, remote control capabilities, and advanced safety mechanisms. These features elevate their reliability and efficiency in critical testing environments.

- Selecting the appropriate programmable power supply requires careful assessment. You need to consider application requirements, desired features, and factors related to long-term usability and adaptability.

Understanding Programmable Power Supplies

Programmable power supplies represent a significant leap from traditional fixed power supplies due to their adjustable settings and software control. Fixed power supplies offer limited flexibility. Unlike them, programmable power supplies can switch between different operational modes. These modes include constant current and constant voltage, which helps meet varying application requirements.

These power supplies are designed to operate across a wide range of parameters. These parameters include voltages, currents, and response speeds. This design makes them versatile for various applications. Enhanced system capabilities and remote control are additional benefits that set programmable power supplies apart from their traditional counterparts.Key Benefits of Programmable Power Supplies

One of the standout features of programmable power supplies is their autoranging capability, which allows them to operate over a wide range of voltages and currents without the need for multiple supplies. This flexibility is further enhanced by interfaces like USB, GPIB, and LAN, enabling diverse ways to control the power supply.

High-quality DC power sources ensure precise and repeatable results, making programmable DC power supplies essential for precision testing applications that demand accuracy. The ability to automate tests not only improves productivity but also enhances the consistency and reliability of results. Remote control capabilities further emphasize the benefits of programmable power supplies. Automating tests with these power supplies boosts productivity and accuracy, establishing them as crucial tools for precise and efficient testing environments.How Programmable Power Supplies Work

At the heart of programmable power supplies is their ability to provide precise control of voltage and current control, a feature critical for high-stakes applications such as military and medical equipment. These power supplies include a processor and specialized circuit for programming voltage and current, along with feedback mechanisms for monitoring and ensuring accuracy. Programmable power supplies utilize analog or digital signals to control output voltage, current, and frequency with high precision. This flexibility allows users to adapt power settings for dynamic testing environments and mission-critical operations. Modern programmable power supplies also feature advanced user interfaces, making them intuitive to operate and enhancing automation in testing environments. These linear power supplies can offer ac power, DC, or both outputs, catering to diverse requirements. They operate over a broad spectrum of voltage levels, current, and power levels, making them suitable for various testing and application scenarios. The right dc power supply with autoranging features further enhances adaptability by automatically adjusting voltage and current output to suit various test conditions.Applications of Programmable Power Supplies

Programmable power supplies are versatile tool suitable for a wide array of applications, including industrial processes, medical systems, and automated testing equipment. Advanced models offer real-time feedback and the ability to manage power remotely, enhancing efficiency and reducing downtime.

In aerospace and defense, programmable DC power supplies simulate extreme conditions like lightning strikes and offer diagnostics for reliable performance. The automotive industry utilizes these dc power supply for EV battery testing, allowing for regenerative energy testing and simulating real-world conditions. For example, these systems can replicate various environmental factors to ensure optimal performance. Renewable energy systems also benefit from programmable power supplies, which can simulate grid conditions for energy storage and solar systems testing. Recent innovations in programmable power supplies include high-frequency operation features, which enable faster response times and reduced testing durations for high-power applications. Bidirectional capabilities allow for both sourcing and sinking of power, improving efficiency and control in testing applications. The integration of AI and machine learning is optimizing testing processes and enhancing energy management across various applications.Selecting the Right Programmable Power Supply for Your Needs

Selecting the right programmable power supply is crucial to meet specific application needs. This involves defining your application requirements and considering essential features and long-term usability to ensure the power supply meets your operational demands effectively.Assessing Your Application Requirements

Understanding your application’s current and voltage ratings is critical to ensuring the power supply meets operational demands. Equally important is determining the number of outputs required for your application, as this will influence the choice of a compatible and efficient programmable power supply, including its output current. Assessing application requirements thoroughly helps in selecting the right solution that meets operational needs effectively. Considering factors like current and voltage ratings alongside the necessary number of outputs ensures that the power supply you choose can handle the varying demands of your test system.Evaluating Essential Features

When selecting a power supply, modular designs are essential for adaptability to future testing needs, ensuring longevity and flexibility. Critical specifications such as output voltage and current capacity must be assessed to ensure consistent performance and reliability in testing applications. Regularly backing up the programming data of programmable power supplies is also crucial for maintaining operational reliability. Precision and stability in output are vital to ensure the power supply performs consistently across different testing scenarios.Long-Term Usability and Flexibility

Long-term usability is a key consideration when selecting a programmable power supply, as it ensures the equipment remains flexible and functional over time. Flexibility allows the power supply to adapt to changing requirements, accommodating unexpected load conditions by allowing for an excess capacity of 10% to 20% over maximum power needs. Remote monitoring and advanced control capabilities enhance the long-term usability of programmable power supplies, ensuring they remain reliable tools for ongoing operations. Such features enable the power supply to operate efficiently and remain stable under varying conditions.Top Programmable Power Supply Models

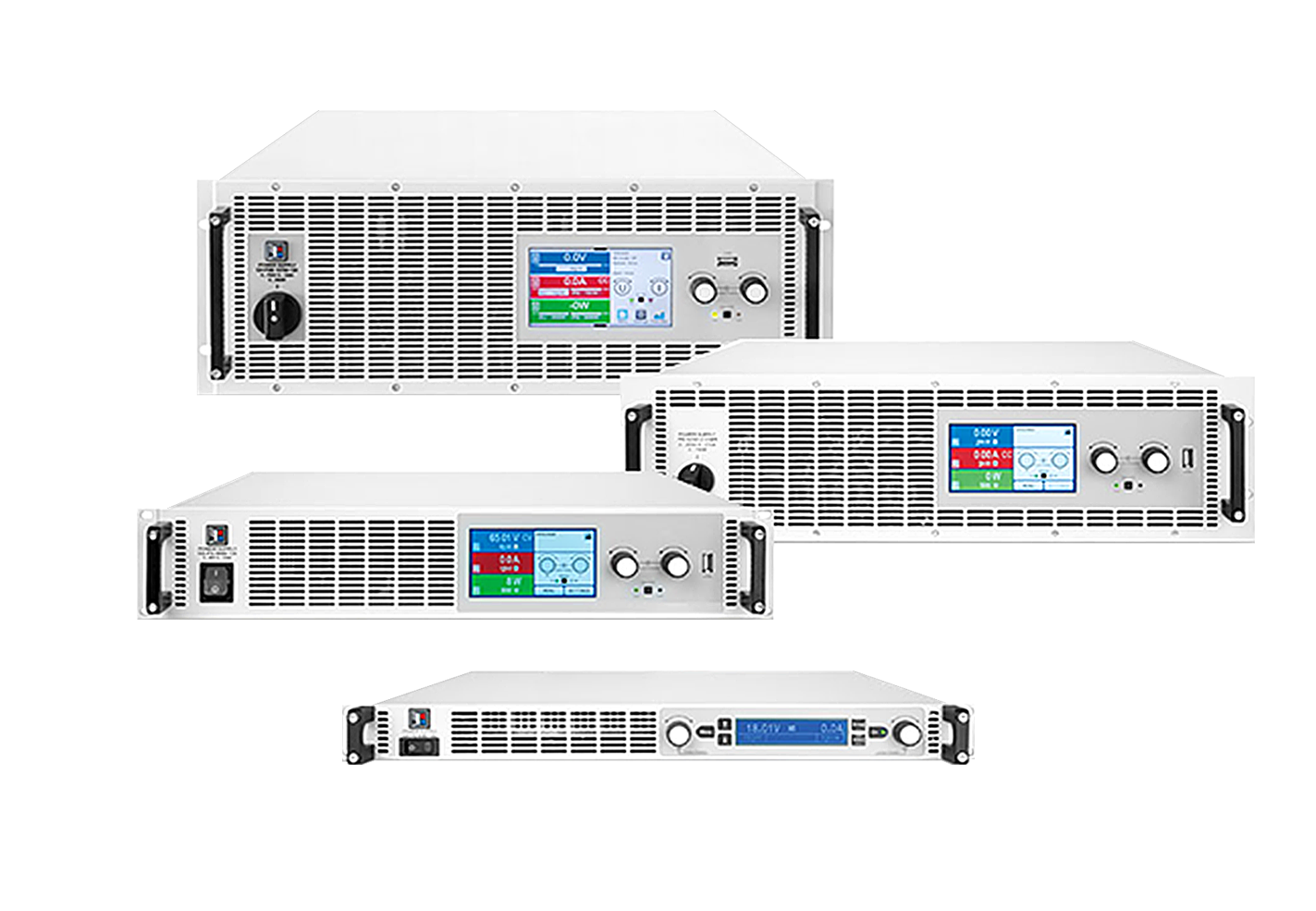

Several top programmable power supply models cater to a range of applications and different power levels, providing full power for various needs. To illustrate, the EA-PSI 9040-60 DT offers a maximum output of 1500 Watts with reliable performance, while the MSI MAG A550BN offers a maximum output of 650 Watts. For more demanding applications, consider these power supplies:- EA-PSI 9040-40 DT: offers up to 640 Watts and is known for its efficient performance..

- EA-PSI 9080-40 DT: delivers 1000 Watts with top-tier efficiency and low noise.

Safety and Protection Features

Programmable power supplies integrate advanced protection features, including short circuit protection, to ensure safety and reliability in various applications. Features such as overvoltage protection, overcurrent protection, and automatic shut-off mechanisms prevent electrical faults and equipment damage, safeguarding both the power supply and connected devices. Stability and reliability during operation are maintained through feedback mechanisms and load regulation, which are essential features for dependable performance in critical applications. These safety features are vital for engineers and technicians who rely on consistent output parameters to ensure the smooth operation of their systems.Maintenance and Support for Programmable Power Supplies

Regular maintenance and support are crucial for the longevity and efficient operation of programmable power supplies. Real-time measurement of parameters enables efficient calibration and troubleshooting, ensuring the power supply operates within safe limits. Routine inspections help identify issues early, reducing the risk of unexpected failures. Maintaining cleanliness by removing dust from computer components can prevent overheating, while environmental monitoring, such as controlling humidity and temperature, ensures optimal speed performance. Additionally, having spare device parts readily available minimizes downtime during maintenance or repairs.Innovations in Programmable Power Supply Technology

Recent innovations in programmable power supply technology are shaping the future of electronic applications. Key aspects include:- Software and firmware updates that optimize the functionality of programmable power supplies.

- Tools like PyVISA that enable seamless communication with instruments.

- Enhanced integration and operation of these power supplies through such tools.