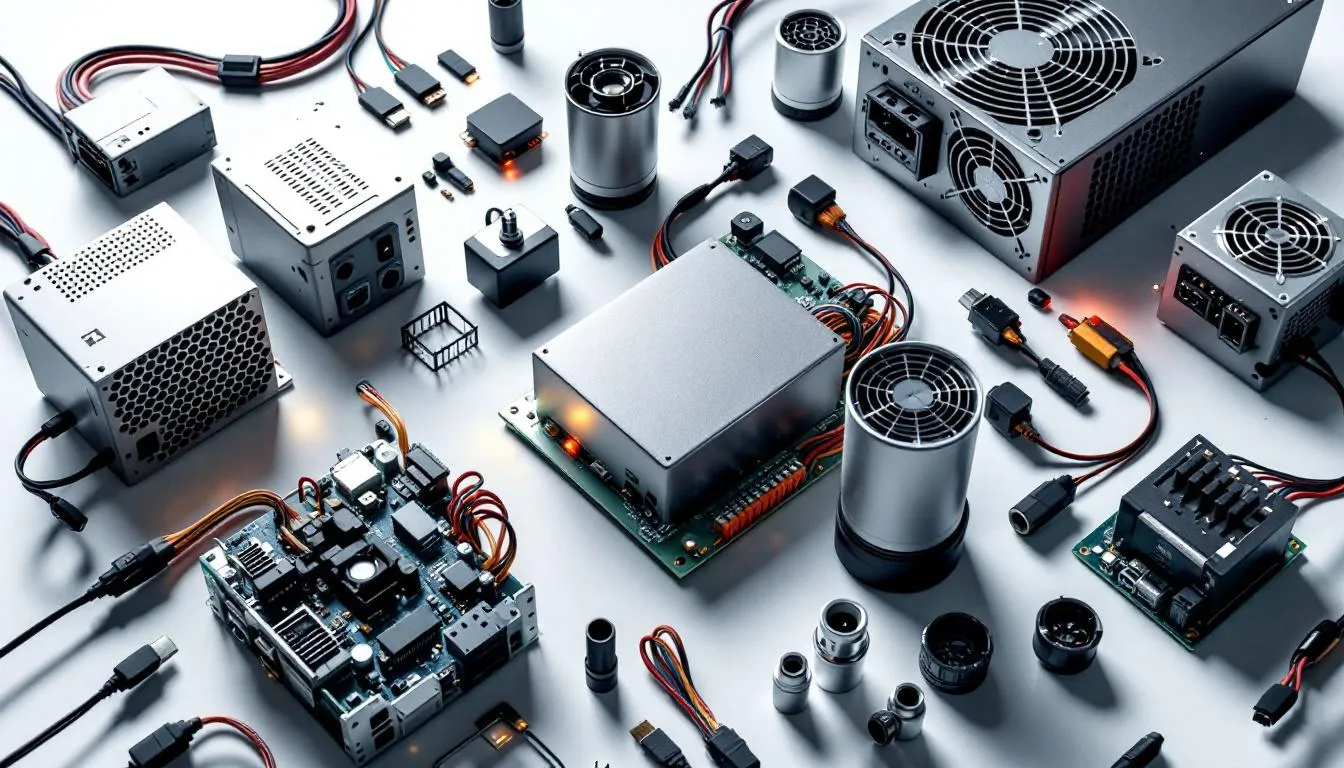

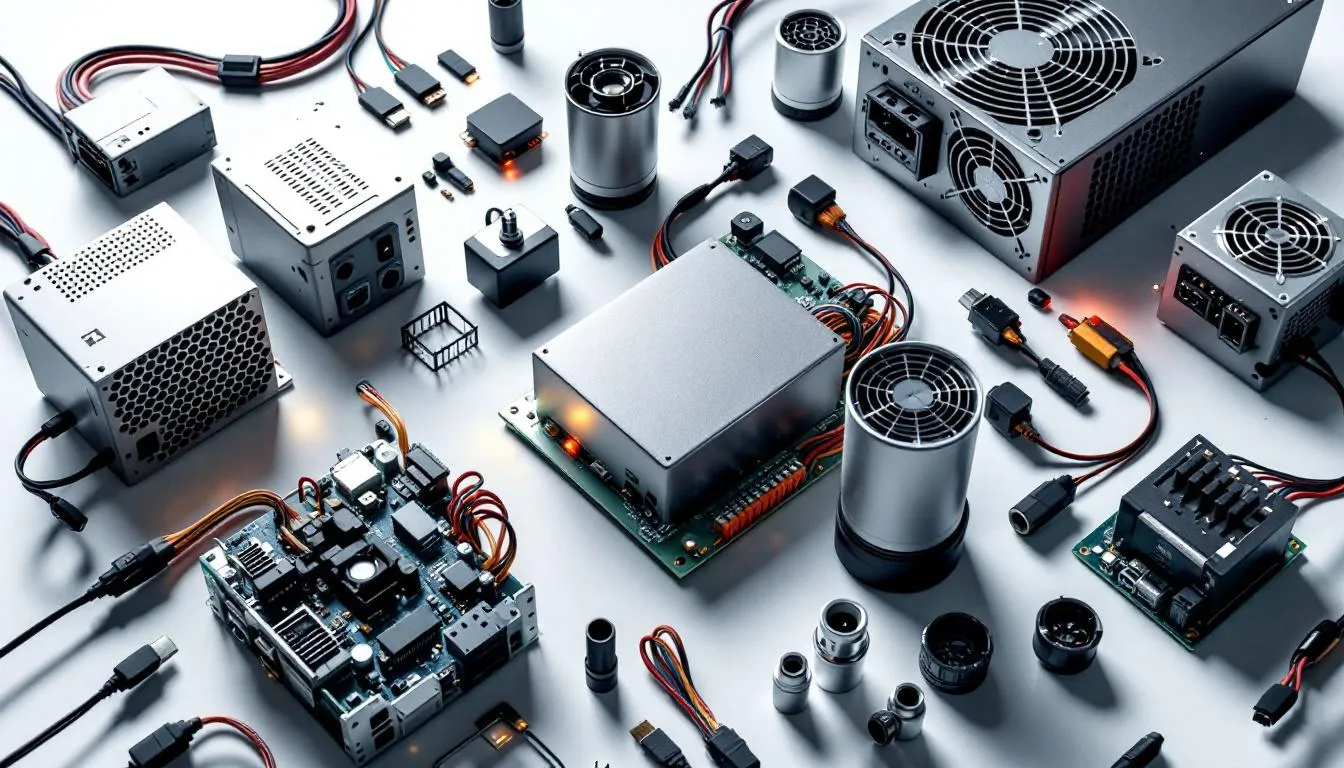

Curious about DIN mount power supplies? These devices are critical in converting AC to DC for reliable power in industrial systems. We’ll break down their key features, why they’re important, and how to choose the right one for your needs.

DIN mount power supplies are specifically engineered to support a myriad of applications in industrial automation, process control, and building management systems. These versatile devices play a critical role in ensuring the stable operation of various equipment, including sensors, programmable logic controllers (PLCs), and actuators. Without these power supplies, maintaining the efficiency and functionality of complex automation systems would be a daunting task.

DIN rail power supplies convert AC voltage into a regulated DC output, ensuring industrial systems remain operational. Their compact design and standardized mounting system facilitate easy integration into control panels, making them a preferred choice for engineers and system designers.

But what sets high-efficiency models apart? Let’s delve into their key features.

DIN mount power supplies are specifically engineered to support a myriad of applications in industrial automation, process control, and building management systems. These versatile devices play a critical role in ensuring the stable operation of various equipment, including sensors, programmable logic controllers (PLCs), and actuators. Without these power supplies, maintaining the efficiency and functionality of complex automation systems would be a daunting task.

DIN rail power supplies convert AC voltage into a regulated DC output, ensuring industrial systems remain operational. Their compact design and standardized mounting system facilitate easy integration into control panels, making them a preferred choice for engineers and system designers.

But what sets high-efficiency models apart? Let’s delve into their key features.

High-efficiency DIN rail power supplies are designed to maximize energy savings and minimize heat generation, with key features including:

High-efficiency DIN rail power supplies are designed to maximize energy savings and minimize heat generation, with key features including:

Modern DIN rail power supplies are marvels of engineering, featuring innovative designs and cooling mechanisms that enhance their efficiency and reliability. Convection cooling is a standout feature, characterized by:

Modern DIN rail power supplies are marvels of engineering, featuring innovative designs and cooling mechanisms that enhance their efficiency and reliability. Convection cooling is a standout feature, characterized by:

In the realm of industrial automation and process control, application analysis services play a pivotal role in optimizing power supply configurations. Simulation software can model different power supply setups, predicting system behavior and identifying potential issues before they arise. This proactive approach ensures system reliability and efficiency, preventing costly downtime.

Companies like PULS, in cooperation with MGV, offer custom solutions tailored to meet specific client requirements. These solutions adapt power supplies to unique applications, providing the ideal balance between performance and cost.

Application analysis services help in making informed decisions for selecting and optimizing DIN mount power supplies, ensuring peak efficiency in your systems.

In the realm of industrial automation and process control, application analysis services play a pivotal role in optimizing power supply configurations. Simulation software can model different power supply setups, predicting system behavior and identifying potential issues before they arise. This proactive approach ensures system reliability and efficiency, preventing costly downtime.

Companies like PULS, in cooperation with MGV, offer custom solutions tailored to meet specific client requirements. These solutions adapt power supplies to unique applications, providing the ideal balance between performance and cost.

Application analysis services help in making informed decisions for selecting and optimizing DIN mount power supplies, ensuring peak efficiency in your systems.

When it comes to DIN rail power supplies, there’s no one-size-fits-all solution. Different applications require different power solutions, and understanding the various product families can help you find the ideal solution. The DIMENSION series, for instance, includes high-end power supplies ranging from 80 to 960 watts, suitable for various input configurations.

For value-oriented solutions, the PIANO series offers outputs of 12, 24, and 48 volts, delivering between 36 to 480 watts. Meanwhile, FIEPOS field power supplies provide a compact and rugged design with IP54, IP65, and IP67 ratings, making them ideal for decentralized applications.

For low-power applications, the MiniLine series offers ultra-compact power supplies with the following features:

When it comes to DIN rail power supplies, there’s no one-size-fits-all solution. Different applications require different power solutions, and understanding the various product families can help you find the ideal solution. The DIMENSION series, for instance, includes high-end power supplies ranging from 80 to 960 watts, suitable for various input configurations.

For value-oriented solutions, the PIANO series offers outputs of 12, 24, and 48 volts, delivering between 36 to 480 watts. Meanwhile, FIEPOS field power supplies provide a compact and rugged design with IP54, IP65, and IP67 ratings, making them ideal for decentralized applications.

For low-power applications, the MiniLine series offers ultra-compact power supplies with the following features:

Key Takeaways

- DIN mount power supplies are essential for industrial automation, converting AC to regulated DC power for reliable operation of equipment like PLCs and sensors.

- High-efficiency models feature energy-saving designs with efficiency ratings up to 95%, reduced heat output, and robust protective features to enhance reliability and lifespan.

- Selecting the appropriate DIN rail power supply requires evaluating input voltage, output power, and environmental conditions to ensure compatibility and optimal performance.

Understanding DIN Mount Power Supplies

DIN mount power supplies are specifically engineered to support a myriad of applications in industrial automation, process control, and building management systems. These versatile devices play a critical role in ensuring the stable operation of various equipment, including sensors, programmable logic controllers (PLCs), and actuators. Without these power supplies, maintaining the efficiency and functionality of complex automation systems would be a daunting task.

DIN rail power supplies convert AC voltage into a regulated DC output, ensuring industrial systems remain operational. Their compact design and standardized mounting system facilitate easy integration into control panels, making them a preferred choice for engineers and system designers.

But what sets high-efficiency models apart? Let’s delve into their key features.

DIN mount power supplies are specifically engineered to support a myriad of applications in industrial automation, process control, and building management systems. These versatile devices play a critical role in ensuring the stable operation of various equipment, including sensors, programmable logic controllers (PLCs), and actuators. Without these power supplies, maintaining the efficiency and functionality of complex automation systems would be a daunting task.

DIN rail power supplies convert AC voltage into a regulated DC output, ensuring industrial systems remain operational. Their compact design and standardized mounting system facilitate easy integration into control panels, making them a preferred choice for engineers and system designers.

But what sets high-efficiency models apart? Let’s delve into their key features.

Key Features of High-Efficiency DIN Rail Power Supplies

High-efficiency DIN rail power supplies are designed to maximize energy savings and minimize heat generation, with key features including:

High-efficiency DIN rail power supplies are designed to maximize energy savings and minimize heat generation, with key features including:

- Efficiency ratings up to 93.5%.

- Some modern designs surpassing 95% efficiency due to innovative switch designs and high-quality components.

- Lower heat output directly correlating with impressive efficiency.

- More compact designs enabled by reduced heat.

- Increased packing density in control cabinets.

Selecting the Right DIN Rail Power Supply for Your System

Selecting the right DIN rail power supply involves more than just picking a device off the shelf. It requires a thorough assessment of your system’s input voltage and output power requirements. With input voltage ranges typically spanning from 90V to 264V AC, these power supplies are designed to accommodate a wide array of applications. However, ensuring they meet recognized safety and EMC standards is crucial for reliable operation in industrial settings. Consulting with experts or using application analysis services helps identify specific power supply needs, optimizing efficiency and assist in reducing operational costs. Next, let’s delve into the specific considerations for industrial applications.Considerations for Industrial Applications

Operating in industrial environments presents unique challenges that must be addressed when selecting a power supply. Factors such as temperature range, vibration resistance, and compliance with safety standards are paramount. DIN rail power supplies that can operate within a wide temperature range, typically from -30°C to +70°C, offer versatile solutions for various applications. Additionally, the potential exposure to dirt, humidity, and vibrations should be assessed to ensure the power supply operates reliably. Choosing power supplies known for high reliability reduces the risk of system failures and minimizes maintenance needs, ensuring consistent performance in critical applications.Matching Power Supplies to Device Loads

Aligning the power supply’s specifications with the device loads it will support at full load is crucial for optimal functionality. This involves:- Considering both voltage and current demands to avoid overload and ensure efficient operation.

- Ensuring power supplies are compatible with the types of loads they serve.

- Paying particular attention to inductive and capacitive loads that can create instability.

Importance of Reliability and Availability

Reliability and availability are non-negotiable in industrial applications. DIN rail power supplies are renowned for their durability, which is critical in demanding environments. High reliability significantly reduces the risk of downtime and maintenance needs, ensuring smooth and uninterrupted operations. Monitoring operating temperatures is crucial. Exceeding specified limits can lead to performance declines and potential failures, underscoring the need for selecting high-reliability power supplies.Innovative Design and Cooling Mechanisms

Modern DIN rail power supplies are marvels of engineering, featuring innovative designs and cooling mechanisms that enhance their efficiency and reliability. Convection cooling is a standout feature, characterized by:

Modern DIN rail power supplies are marvels of engineering, featuring innovative designs and cooling mechanisms that enhance their efficiency and reliability. Convection cooling is a standout feature, characterized by:

- Relying on natural airflow rather than fans to dissipate heat

- Reducing the need for external cooling systems

- Enhancing overall reliability by minimizing moving parts that could fail

Application Analysis Services

In the realm of industrial automation and process control, application analysis services play a pivotal role in optimizing power supply configurations. Simulation software can model different power supply setups, predicting system behavior and identifying potential issues before they arise. This proactive approach ensures system reliability and efficiency, preventing costly downtime.

Companies like PULS, in cooperation with MGV, offer custom solutions tailored to meet specific client requirements. These solutions adapt power supplies to unique applications, providing the ideal balance between performance and cost.

Application analysis services help in making informed decisions for selecting and optimizing DIN mount power supplies, ensuring peak efficiency in your systems.

In the realm of industrial automation and process control, application analysis services play a pivotal role in optimizing power supply configurations. Simulation software can model different power supply setups, predicting system behavior and identifying potential issues before they arise. This proactive approach ensures system reliability and efficiency, preventing costly downtime.

Companies like PULS, in cooperation with MGV, offer custom solutions tailored to meet specific client requirements. These solutions adapt power supplies to unique applications, providing the ideal balance between performance and cost.

Application analysis services help in making informed decisions for selecting and optimizing DIN mount power supplies, ensuring peak efficiency in your systems.

Product Families and Custom Solutions

When it comes to DIN rail power supplies, there’s no one-size-fits-all solution. Different applications require different power solutions, and understanding the various product families can help you find the ideal solution. The DIMENSION series, for instance, includes high-end power supplies ranging from 80 to 960 watts, suitable for various input configurations.

For value-oriented solutions, the PIANO series offers outputs of 12, 24, and 48 volts, delivering between 36 to 480 watts. Meanwhile, FIEPOS field power supplies provide a compact and rugged design with IP54, IP65, and IP67 ratings, making them ideal for decentralized applications.

For low-power applications, the MiniLine series offers ultra-compact power supplies with the following features:

When it comes to DIN rail power supplies, there’s no one-size-fits-all solution. Different applications require different power solutions, and understanding the various product families can help you find the ideal solution. The DIMENSION series, for instance, includes high-end power supplies ranging from 80 to 960 watts, suitable for various input configurations.

For value-oriented solutions, the PIANO series offers outputs of 12, 24, and 48 volts, delivering between 36 to 480 watts. Meanwhile, FIEPOS field power supplies provide a compact and rugged design with IP54, IP65, and IP67 ratings, making them ideal for decentralized applications.

For low-power applications, the MiniLine series offers ultra-compact power supplies with the following features:

- Outputs ranging from 5 to 48 volts

- Power capacities of 15 to 100 watts

- Support for multiple output configurations, catering to various industrial needs.

Installation and Maintenance Tips

Proper installation and maintenance of DIN rail power supplies are essential for longevity and optimal performance. These modular devices are designed for easy installation and efficient space use, making them ideal for constrained environments. To properly mount and maintain DIN rails:- Install DIN rails on a clean, flat surface using appropriate fasteners to prevent wobbling.

- Regularly tighten screws as vibrations may loosen them over time.

- Clean regularly with a soft, dry cloth to prevent dust accumulation and ensure optimal operation.

- Inspect DIN rails periodically for cracks or other forms of damage.

- Ensure all connections are properly grounded to avoid electrical faults and equipment damage.

- Mark and label DIN rails clearly to facilitate easy identification of mounted components during maintenance.